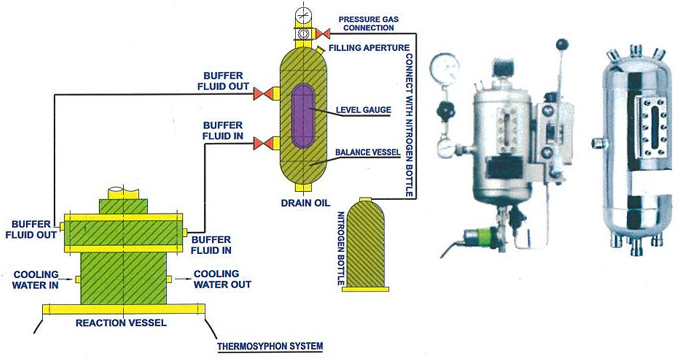

Series : GTS-1

The Globe Star Engineer provides precisely engineered thermosyphon system made of finest quality material that is SS 304/SS 316. We have developed GTS – 1series of thermosyphone system. It is storage and pressurizing unit. The thermosyphon system is a very effective system, used with double mechanical seals as back to back or tandem seal arrangement. The cooling coil is used to bring down the temperature of barrier fluid flowing to thermosyphon from the seal.

Accessories

-

Pressure Gauge (0-40 kg/cm ): To Measure the Pressure Inside Vessel

-

Level Gauge : To Indicate the liquid level Inside the Vessel

-

Hand Pump : To Recharge the Thermosyphon vessel with Additional Quantity of Barrier Fluid when Thermosyphon is under Pressure and Liquid level is Low.

Metal Parts

-

Thermosyphon Shell : Carbon Steel : SS 304/SS 316

-

Cooling Coil : SS 304/SS 316

-

Empty Weight : 32 (kg/cm )

Operating Limits

-

Capacity - 7.5 Litres

-

Design Pressure - 10 bar (kg/cm 2)

-

Hyd. Test Pressure -15 Bar (kg/cm 2)

-

Max Working temp - 150°c

-

Heat Transfer Area of Cooling Coil : 0.226 m

-

Cooling Water Flow Rate Recommended : 10 Litre/min

Connection Specifications

-

Cooling Water Inlet : 1/2" NPT (F)

-

Cooling Water Outlet : 1/2"NPT (F)

-

Buffer Inlet : 1/2" NPT (F)

-

Buffer Outler : 1/2" NPT (F)

-

Pressure Gauge Connection : 3/8" NPT (F)

-

Filling Connection : 1/2" NPT (F)

-

Pressure Gas Connection : 1/2" NPT (F)

-

Refilling Connection : 1/4" NPT (F)

-

Drain : 1/2" NPT (F)

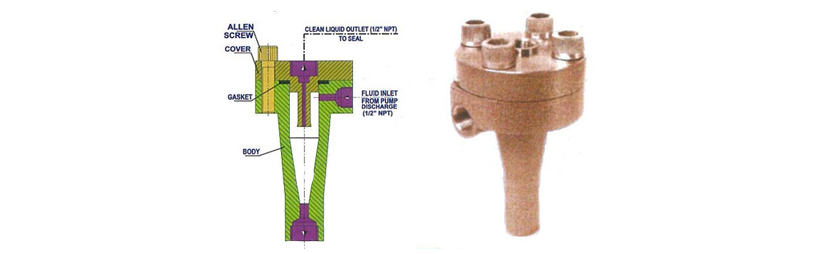

Cyclon Separator :- Series : GCS-1

The globe star engineer fabricates the system, the cyclone separator to separate the solid particles from the liquid. We have designed and developed the GCS -1 series of the cyclone separator. The 80% of the liquid is separated from the solid particles and the clear liquid is sent to the seal chamber. Remaining 20% liquid with solid particles, sent back to the suction of the pump.

Operating Limits

-

Density of Solid Particles has to be more than liquid

-

Maximun Solid Contents > 10% by weight

-

Max Viscosity of liquid 20 centistokes

-

Pressure Differential Desired : 2 to 8.5 bar (kg)

Technical Specifications

-

Size :- 1/2"

-

Max Temp - 125°c

-

Max Pressure 60 bar (kg/cm 2)

-

Material of construction

-

Hardware-SS 304/SS 316

-

Packing - Teflon